The casting simulation software: cutting-edge technology used by Fonderia Morini

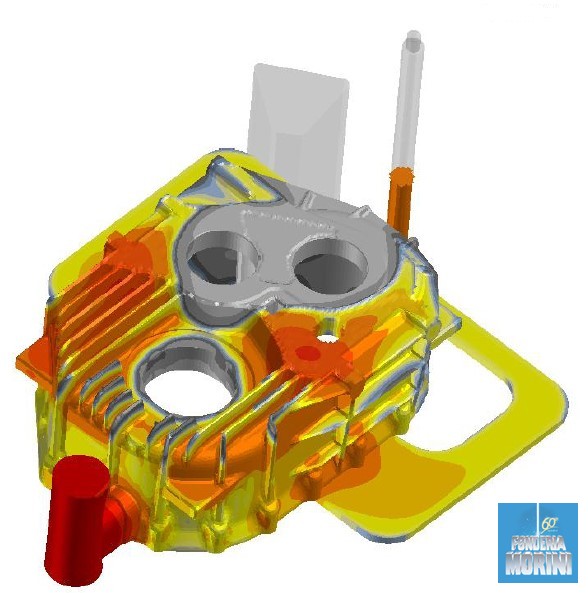

The ProCAST casting simulation software has been included in Fonderia Morini’s technological equipment for highly complex projects. This advanced tool indeed allows to reduce the waste and manufacturing times required to obtain a satisfactory product.

In the past, for a qualitatively satisfactory casting several samples were required. Test after test, errors were corrected and parts not up to par were adjusted. This was obviously costly for both foundries and customers, and it significantly slowed down the production times.

With the casting simulation software, on the other hand, several simulations are prepared until the result is acceptable for production. This way, it is possible to create a mould that is qualitatively satisfactory from the first sample, saving time and resources.

Fonderia Morini’s quality in the future

To keep up with the most modern upgrades, Fonderia Morini is evaluating investments in 3D printers for the future. The company could thus create prototypes in even shorter times and provide the customer with a reference that allows them to establish whether or not to proceed with production.

In the next article, we will deepen these topics with a video interview with Antonio Magnani, Quality Manager at Fonderia Morini.

Italiano

Italiano  Deutsch

Deutsch  Français

Français